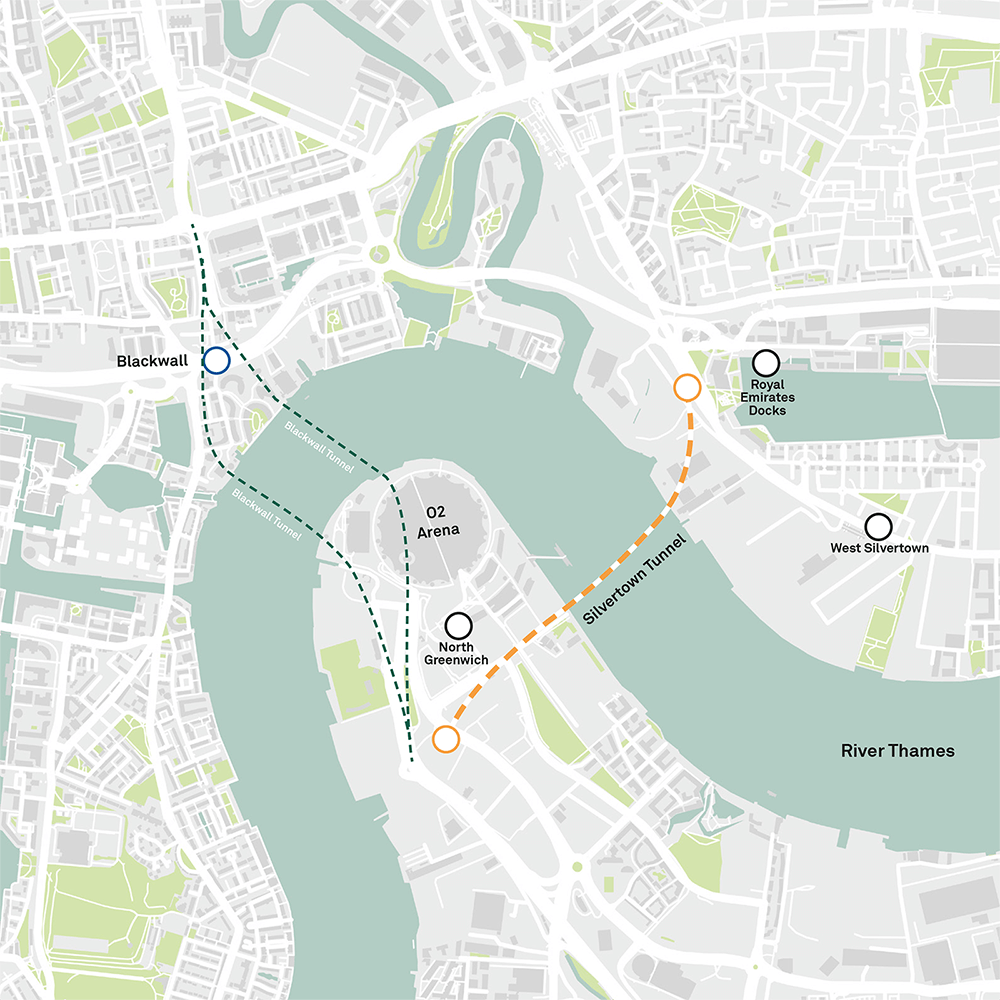

The Silvertown Tunnel is a new 1.4 km twin-bore road tunnel in East London, connecting the Greenwich Peninsula and the west Silvertown district under the River Thames. The design includes the road tunnel, as well as 0.6 km of access ramps, maintenance buildings and an above ground road, including a highway bridge and a footbridge.

Due to open in 2025, the Silvertown Tunnel project has been designed to significantly reduce congestion in and around the neighbouring 122-year-old Blackwall tunnel, with motorists suffering from an estimated one million wasted hours each year queuing for the tunnel. The new tunnel is the first major road crossing the River Thames since the Queen Elizabeth II Bridge at Dartford opened in October 1991, and the project will result in a six-fold increase in public transport provision across this area of the River Thames.

In 2016, Transport for London began the tendering process for the construction of the new tunnel. The finalists were shortlisted in 2017, and in 2019 the RiverLinx Consortium were awarded the design, construction, and maintenance contract.

Design and construction of the Silvertown Tunnel is being delivered by Riverlinx CJV, a joint venture bringing together global expertise from three civil engineering and construction companies: Ferrovial Construction, BAM Nuttall and SK Ecoplant.

Efficiently capture images and measure points

One tunnel boring machine (TBM) with a diameter of 12m will be used to bore both tunnels. The TBM will launch in Silvertown to bore the first tunnel, then rotate in North Greenwich and return under the River Thames to Silvertown to bore the second tunnel, with all suitable excavated material being transported by river to minimise the impact for neighbouring communities and routes. With over 600,000 m2 of material being excavated, the scale of the project mean that the Surveying teams required a solution to quickly and efficiently capture images and measure points. SCCS provided and supported the surveying and engineering teams with some of the latest equipment from Leica Geosystems.

The chosen solution, the Leica GS18I GNSS RTK Rover, proved to be the most accurate and easy to use GNSS RTK Rover tested for the project. Utilising highly innovative Visual Positioning technology based on seamless integration of GNSS, IMU and a camera, the solution enabled RiverLinx CJV to measure survey grade points in images on-site and in the office and to create point clouds from captured data.

After demonstrations of the GS18I, it became apparent the imaging capabilities could not be ignored. Overly impressed with its ability to capture the required images and measure the points, the team could not only benefit from costs savings but also enjoy the improved functionality and efficiencies.

“Key benefits to us with the GS18I with capturing data and setting out has been increasing productivity with our survey crews saving time and costs”

Hugo Canales – Survey Manager, Riverlinx CJV

Designed to measure large amounts of points efficiently, the GS18I allowed RiverLinx CJV to capture images and measure hundreds of points within minutes, often in locations on site which could not be physically accessed. Using images to measure these points, RiverLinx CJV reduced the amount of time they had to spend on-site and cut down on re-works. Once the site was captured, they had every detail measured.

Imaging power has changed the rules of the game. By having the power to measure what they saw, RiverLinx CJV could reach places that they couldn’t before without switching tools or climbing through obstacles. This gave them flexibility in the field, freed up equipment and team, and maximised productivity.

With construction now fully underway with initial excavation, piling supported with continued monitoring of infrastructure, the Leica Viva TS16 total stations, LS10 digital levels and the GS18I are crucial to this project.

Throughout the project, Ben du Preez from Leica Geosystems and the SCCS team have provided training and technical support for all of the solutions being used during the construction.

“The support so far has been very professional, either with pre-purchase and/or post-purchase periods. I’ve got nothing negative to say about Ben and the team, they have been very professional, and I do personally really appreciate their knowledge with the equipment that they offered to us.”

Hugo Canales – Survey Manager, Riverlinx CJV